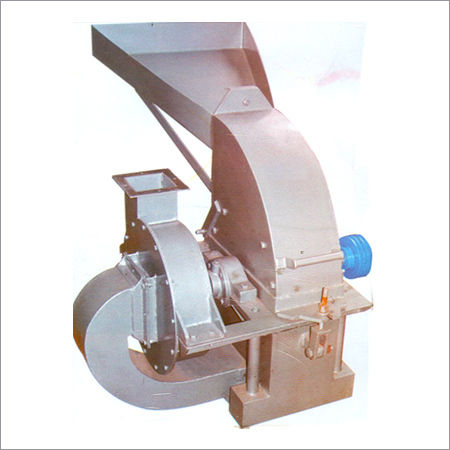

Hammer Grinder

Price 45000 INR/ Unit

Hammer Grinder Specification

- Temperature

- Ambient

- Usage & Applications

- Grinding spices, herbs, cereals, grains, pulses, agro products, feeds, chemicals, minerals, etc.

- Noise Level

- Less than 85 db

- Phase

- Single Phase / Three Phase

- Type

- Hammer Grinder

- Material

- Mild Steel

- Computerized

- No

- Dimension (L*W*H)

- Varies as per model (Approx. 1200x700x1500 mm)

- Color

- Blue & Metallic Grey

Hammer Grinder Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 15 Units Per Week

- Delivery Time

- 15 Days

About Hammer Grinder

Features

- Energy efficient

- Easy to maintain

- Compatible with various items

Main body is made of Mild Steel or stainless steel according to the nature of grinding material. Shaft is made of Mild Steel or stainless steel fitted with discs having hammers. Hammers are made of Mild Steel. EN-8, EN-31, and stainless steel. The outboard bearing design and dual "O" ring seals fitted on the dust proof housing with heavy-duty roller bearing that provide a more dust controlled grinding environment. Fineness can be obtained by using the different types of screens. Light particles up to 300 meshes can be collected. Machine has 4000 to 6000 R.P.M. hard materials and wet materials having the moisture up to 30% can be grinded very easily Pew offers Hammer Mill this is a multi-purpose economy mill that can handle soft, medium, hard, lumpy and irregular sized materials to produce coarse to medium fine powder.

It is used for a wide range of applications in a number of processing fields. These include Spices, Chillies, Coriander, Mix Masala, Ayurvedic Herbal, Food Stuff, Maize, Cattle & Poultry Feed, Tea, Coffee, Paper, Plastics, Sugar, Soya Bean, Gelatin etc. Some of its features include simple & sturdy construction, good grinding efficiency, dust free operation, consistent performance, Low temperature rise for heat sensitive material. Moreover, it retains flavor as well as taste and color to optimum level.

Sizes of Pulverisers: 12" inch, 14" inch, 16" inch, 18" inch, 20" inch, 24" inch, 30" inch.

Out Standing Features

- Grinder is made of food high quality mild steel

- This Grinder is used only for grinding

- Pew Grinder has no vibration, no noice ensure good environment to work

- User friendly machine

| Machine Size | H.P. Required | Capacity Per/H | RPM Required | Hammers |

| 12" | 3 to 5 H.P. | 15 to 50 Kg. | 4600 RPM | 15 |

| 14" | 7.5 to 10 H.P. | 100 to 200 Kg. | 4000 RPM | 24 |

| 16" | 15 to 20 H.P. | 150 to 300 Kg. | 4000 RPM | 24 |

| 18" | 30 H.P. | 200 to 350 Kg. | 3500 RPM | 36 |

| 20" | 40 to 50 H.P. | 300 to 500 Kg. | 3500 RPM | - |

| 24" | 60 to 75 H.P. | 600 to 1500 Kg. | 3500 RPM | - |

| 30" | 75 to 100 H.P. | - | - | - |

Motor 1440 RPM required in all above machine

Versatile Grinding Capabilities

This hammer grinder is engineered to seamlessly process a diverse range of materials such as spices, herbs, grains, pulses, agro products, feeds, chemicals, and minerals. Its toughness and adaptability make it an optimal tool in manufacturing, food processing, and agricultural industries, ensuring finely ground output every time.

Engineered for Efficiency and Durability

Constructed from high-quality mild steel, this grinder is built to last, withstanding regular use in demanding environments. The design supports both single phase and three phase operations, making it a smart investment for businesses with varied electricity requirements. Its efficient grinding process also ensures quiet operation, with noise levels kept below 85 db.

FAQs of Hammer Grinder:

Q: How does the hammer grinder operate for different applications?

A: The hammer grinder uses rapidly rotating hammers to pulverize and grind materials, making it suitable for processing spices, herbs, cereals, grains, pulses, feeds, chemicals, and minerals. Its design ensures efficient and consistent grinding for both small and large-scale operations.Q: What materials can be processed with this hammer grinder?

A: You can use this hammer grinder to process a wide range of materials, including spices, herbs, cereals, grains, pulses, agro products, animal feeds, chemicals, and minerals. Its robust build supports versatile industrial and commercial applications.Q: When is it optimal to use a hammer grinder over other types of grinders?

A: A hammer grinder is most suitable when you need to achieve fine and uniform particle sizes, especially with tough or fibrous materials. It excels in environments where consistent output, reliability, and low noise are important factors.Q: Where can I install and operate this hammer grinder?

A: This grinder is suitable for installation in food processing units, manufacturing facilities, agricultural processing plants, chemical industries, and feed mills. Its compact dimensions and robust build allow flexible placement indoors with standard ambient temperatures.Q: What is the process involved in using this hammer grinder?

A: Simply feed the raw material into the hopper, and the machines rotating hammers will pulverize the material. The ground product is then collected from the output chute. It requires standard electrical connections (single or three phase) and minimal setup.Q: What are the main benefits of using this hammer grinder?

A: The primary benefits include efficient grinding, versatility in material compatibility, sturdy mild steel construction, low operational noise, and compatibility with various electrical setups. These features help enhance productivity and ensure reliable, long-term performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Machinery Category

Automatic Vibro Sifter

Price 90000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel (SS304/SS316)

Type : Other, Automatic Vibro Sifter

Phase : Single or Three Phase

Color : Silver

Conical Screw Mixer

Price 90000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel (SS 304/316)

Type : Other, Conical Screw Mixer

Phase : Three Phase

Color : Silver (standard SS finish)

Pin Mill Machine

Price 45000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Type : Other, Pin Mill Machine

Phase : Single/Three Phase

Color : Silver

Mass Mixer

Price 45000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel (SS 304/316)

Type : Other, Mass Mixer

Phase : 3 Phase

Color : Metallic Silver

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese